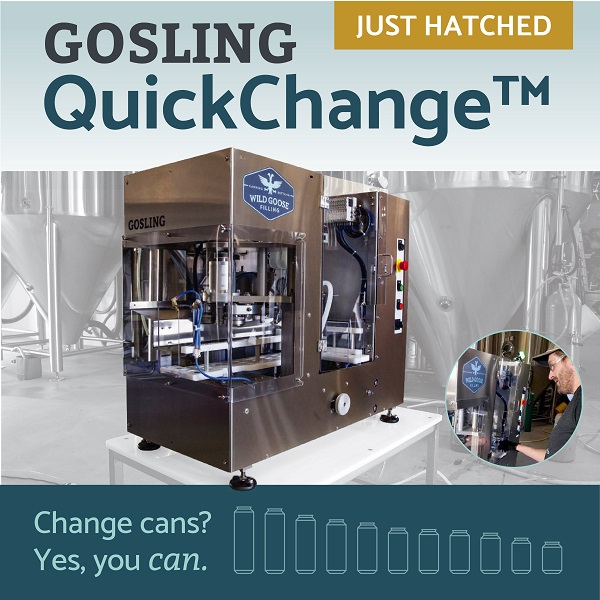

LOUISVILLE, Colo. — Wild Goose Filling has released a QuickChange™ edition of its popular Gosling™ canning system to accommodate multiple can heights. The Gosling QuickChange offers professional, automated beverage canning for small production volumes and makes changing can sizes simple. The system incorporates Wild Goose’s proven seaming and filling technology to deliver the same quality and consistency as the company’s higher speed machines.

The Gosling QuickChange accommodates can sizes from 3” to 8” tall. Breweries and other beverage makers can utilize the machine’s flexibility to expand distribution placement opportunities, offer special sizes for limited releases and easily adapt to changing can supply availability. The system’s design allows craft producers to start with any planned can heights and add new sizes as needed in the future.

Switching between can sizes takes less than 30 minutes with minimal change parts. The Gosling QuickChange gives users the option to simultaneously adjust both the seamer and lid placement station, maintaining repeatability and precision seam integrity across can heights. Operators do not need to level or re-synchronize the seamer and lid dropper platforms between changeovers.

Along with Wild Goose’s still-and-sparkling Gosling Nitro and standard Gosling, the Gosling QuickChange gives beverage producers the ability to can on a smaller scale than traditional automatic systems while protecting the integrity and shelf life of their products. In addition, the company’s new Gosling ProLaunch Pack helps producers get started canning on Gosling systems easily and cost-effectively. The Gosling QuickChange joins Wild Goose’s range of best-selling canning and bottling machines geared towards craft beverages worldwide.

About Wild Goose Filling

With decades of experience in brewing, canning and bottling craft beverages, Wild Goose Filling designs filling systems for beer, cider, kombucha, cannabis, wine, seltzer and other ready-to-drink beverages. Wild Goose pioneered the first craft canning and bottling systems on the market, innovating patented technology that maintains the highest quality levels for packaged beverages. The company engineers and manufactures equipment from its headquarters in Louisville, Colorado and operates offices in Europe along with a network of global partners. Wild Goose has sold 2,200 canning and bottling systems in more than 65 countries.

For more information: https://wildgoosefilling.com/